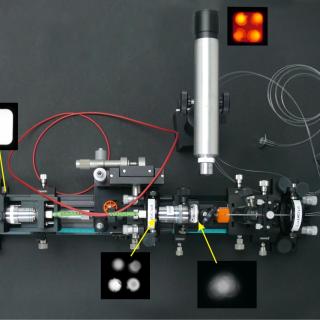

The astronomical observation in the infrared requires the use of cryogenic systems where the detector (infrared sensor) and the entire optical system that accommodates the light from the telescope to the sensor (lenses, mirrors, mechanisms, structures, etc.) is cooled down to temperatures of the order of 200 degrees below zero in a high vacuum environment. The design and integration of the different optical, mechanical and electronic components that must work together at such low temperatures and in a vacuum, requires very specialized technical knowledge. The IAC has extensive experience in the development of infrared instrumentation with open cycle, closed cycle or hybrid cycle coolers. In the latter case, liquid nitrogen is usually used to precool the entire instrument, and a mechanical cooler to keep it in cryogenic conditions. The specialization consists in mastering the techniques of design and manufacture of vacuum chambers, cooling systems, radiation screens and cryo-mechanisms, thermomechanical analysis, and the design of cryogenic opto-mechanical systems, structures and optical benches. The techniques of cryogenics and vacuum are increasingly of industrial interest for their applications in other fields such as medicine, energy and the environment.